3D Printing: A Beginner's Guide to Making Things

Ready to jump into the world of 3D printing? This revolutionary technology is transforming how we design and create objects, offering incredible potential for businesses and individuals alike. But with different 3D printing types and a range of services available, it can feel overwhelming to get started.

This guide will equip you with the knowledge you need to navigate the exciting world of 3D printing. We'll explore the most common printing methods, delve into the benefits of customization, and even peek into the future of this cutting-edge technology. Let's dive in!

Unveiling the Toolbox: 3D Printing Technologies

3D printing isn't magic (although the results might seem like it sometimes!). It's a process that builds objects layer by layer based on a digital design file. But there's more than one way to achieve this feat. Here are three of the most widely used 3D printing technologies:

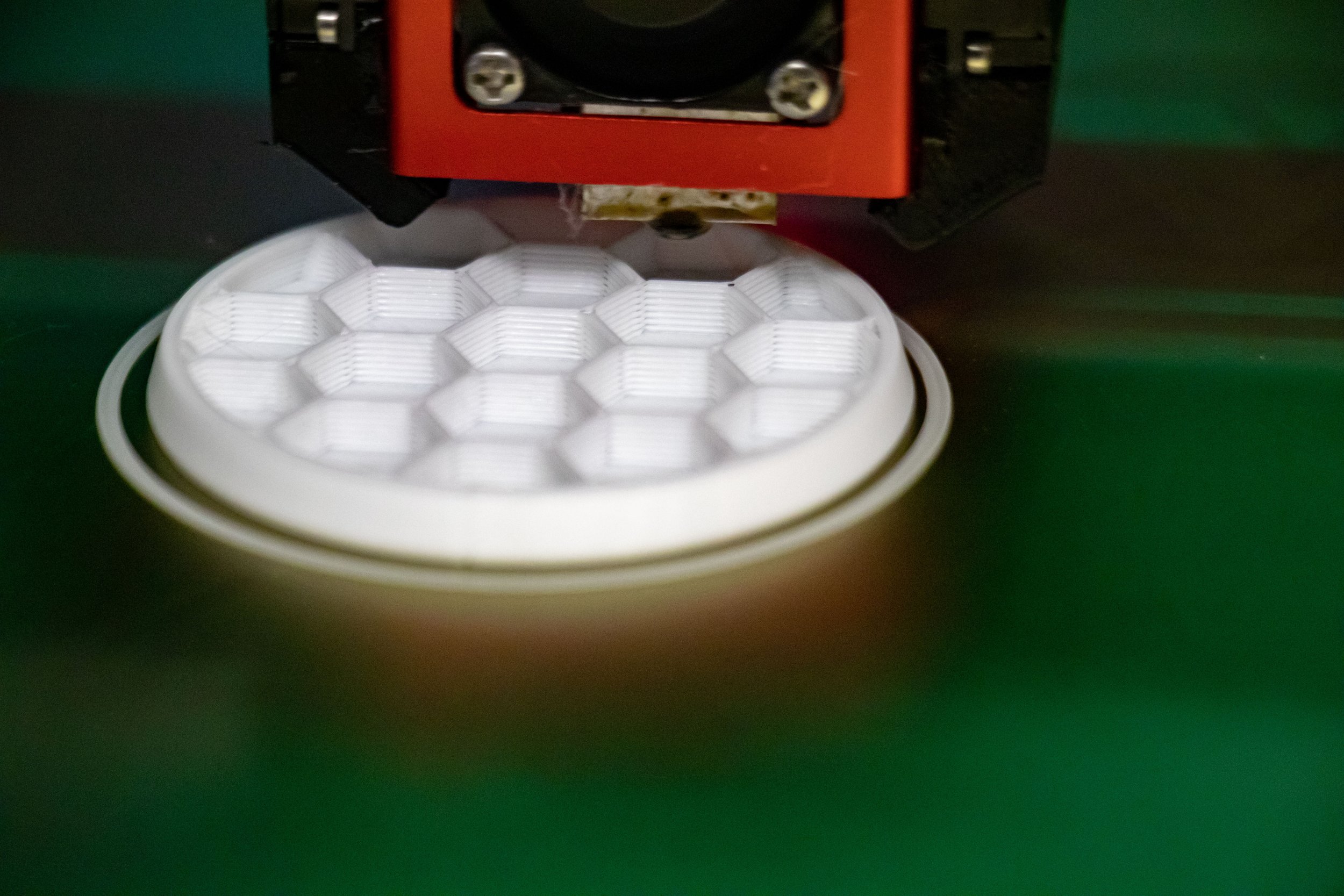

FDM Printing (Fused Deposition Modeling):

Imagine a hot glue gun that builds with plastic instead of glue. FDM printing works similarly, using a heated nozzle to melt filament (think thin plastic wire) and deposit it layer by layer. This affordable method is ideal for creating prototypes, functional parts, and even everyday objects.

SLA Printing (Stereolithography):

For high-resolution printing with incredible detail, SLA takes the crown. This process uses a laser to cure liquid resin into solid layers, resulting in smooth, accurate models. SLA 3D Printing is perfect for detailed prototypes, medical models, and even jewelry. Keep in mind that SLA parts often require post-processing for a polished finish.

PolyJet Printing:

If full-color printing and intricate details are your priorities, PolyJet might be the perfect match. This method uses inkjet technology to jet photopolymers (think light-curable resins) onto the build platform, allowing for multi-material printing and stunningly detailed models. PolyJet Printing excels at creating prototypes, detailed figurines, and even functional end-use parts.

Choosing Your Weapon: How 3D Print Craft Can Help

Not sure which 3D printing method is right for your project? Don't worry, you don't have to go it alone! 3D PrintCraft's team of experts can guide you through the process, considering factors like the desired material, complexity of your design, and of course, your budget. We'll help you choose the most suitable 3D printing technology to bring your vision to life.

But it doesn't stop there. When selecting a 3D printing service, consider turnaround time, available post-processing options, and of course, expertise. 3D PrintCraft checks all the boxes, ensuring you get not only the right technology but also exceptional service and quality results.

Customization and Design Optimization

One of the biggest advantages of 3D printing is the freedom it offers for customization. Forget one-size-fits-all! With 3D printing, you can create objects tailored to your exact needs and preferences. Want a phone case with a custom design? A prosthetic limb perfectly designed for your comfort? 3D printing makes it possible.

But don't worry if your design skills are a work in progress. 3D Print Craft can also assist with design optimization for 3D printing. We can help you lightweight your design for efficiency or check for printability issues to ensure a smooth printing process.

Industries Transformed: 3D Printing's Impact

3D printing isn't just a cool hobby; it's revolutionizing entire industries. From aerospace to healthcare and automotive, 3D printing is changing the way we design, prototype, and manufacture products.

Imagine creating lightweight drone parts for superior flight performance. Picture 3D-printed prosthetics that perfectly match a patient's needs. Even car components with complex geometries are now being 3D printed for improved performance and design freedom. These are just a few examples of how 3D printing is transforming the world around us.

The Finishing Touches: The Importance of Post-Processing

Think 3D printing is a one-step process? Not quite! Sometimes, 3D printed parts require post-processing to achieve the desired look and functionality. This might involve removing support structures used during printing, sanding for a smooth finish, or polishing for a professional shine.

Don't let post-processing intimidate you! 3D PrintCraft offers a range of post-processing services to ensure your 3D printed parts look their absolute best. We'll handle the finishing touches, so you can focus on the joy of using your creation.

Exciting (Future) Trends in 3D Printing

The world of 3D printing is constantly evolving, with new advancements emerging that feel like science fiction straight out of a movie. Here are just a few glimpses of what the future holds:

Multi-material Printing: Imagine printing a single object with different properties in different areas. Think a shoe sole that's both flexible and shock-absorbent, or a tool with a handle comfortable to grip and a tip made of ultra-strong steel. Multi-material printing promises to revolutionize product design and functionality.

Bioprinting: Get ready for even more mind-blowing applications! Bioprinting uses biocompatible materials to create living tissues and even organs. This holds immense potential for regenerative medicine, offering hope for patients with organ failure or severe injuries.

4D Printing: Buckle up, because 3D printing might soon become 4D printing! This futuristic concept involves printing objects that can transform or react to their environment. Imagine a cast that adjusts as your broken bone heals, or a self-assembling piece of furniture. The possibilities are truly endless!

These are just a peek into the exciting future of 3D printing. As technology continues to advance, we can expect even more groundbreaking applications that will reshape our world in ways we can only begin to imagine.